Thioacetic acid Chemical Safety Technical Specification

Release time:2024-05-31

Product recommend and Restricted Use: Determination of Cobalt and Lead. Determination of molybdenum. In dilute ammonia solution instead of hydrogen sulfide as metal precipitant. Synthesis of thioaldehydes and thiones. In histochemistry as a substrate for cholinesterase.

Chemical Safety Technical Instructions

Revision date: 8 September 2021

Number: 01

Product Name: Thioacetic acid

Version: 02

Part I

Chemicals and corporate identification

Chemical Chinese name: Thioacetic acid

Chemical English name: Thiolacetic acid

Company: Wuxue Rongtai Pharmaceutical Technology Co., Ltd.

Enterprise address: Wuxue Tianzhen Office Makou Industrial Park

Zip Code: 435400

Fax: 0713-3661166

Tel: 0713-8529666

Email address: 515730808@qq.com

Enterprise Emergency Phone: 0713-3661088

Product recommend and Restricted Use: Determination of Cobalt and Lead. Determination of molybdenum. In dilute ammonia solution instead of hydrogen sulfide as metal precipitant. Synthesis of thioaldehydes and thiones. In histochemistry as a substrate for cholinesterase.

Part II

Hazard Overview

Emergency overview: this product is flammable, corrosive, strong irritation, can cause human body burns.

GHS Hazard Categories: Flammable Liquid -2, Severe Eye Damage/Eye Irritation -1, Skin Corrosion/Irritation -1, Respiratory or Skin Sensitization-Skin Sensitization -1,

Label Elements:

Pictograms:

Warning word: Danger

Hazard information: Highly flammable liquids and vapors; cause serious eye damage; cause severe skin burns and eye damage; may cause skin allergic reactions;

Precautionary Notes:

Preventive measures: Keep away from fire and heat sources, and smoking is strictly prohibited in the workplace. Avoid contact with eyes, skin, wash thoroughly after operation. Avoid breathing gas. Operate only outdoors or in well-ventilated areas. Wear protective gloves/protective clothing/protective glasses/protective face mask. Discharge into the environment is prohibited.

Accident response: evacuate the personnel from the leakage pollution area to the safety area, and isolate them. Strictly limit and cut off the leakage source as much as possible to prevent entering into the restricted space such as sewer and flood discharge ditch. In case of skin contact, immediately remove contaminated clothing and rinse with plenty of flowing water for at least 15 minutes. Seek medical attention. In case of eye contact, immediately lift the eyelid and rinse thoroughly with plenty of flowing water or saline for at least 15 minutes. Seek medical attention. If inhaled, quickly leave the site to fresh air. Keep the airway unobstructed. If breathing is difficult, give oxygen. If breathing stops, give artificial respiration immediately. Seek medical attention. If ingested by mistake, drink plenty of warm water, induce vomiting, and seek medical attention.

Safe storage: airtight operation, strengthen ventilation.

Disposal: refer to relevant national and local regulations before disposal. Incineration method is recommended for disposal. The sulfur oxides discharged from the incinerator are removed by a scrubber.

Physico-chemical hazard: Extremely flammable liquid. With the air can form an explosive mixture, fire, high heat caused by combustion explosion.

Health hazard: This product is a tear gas. Steam on the nose, throat and skin have a strong stimulating effect, and can be absorbed through the skin and poisoning. Symptoms and signs of irritation of the skin and mucous membranes, especially of the eyes and upper respiratory tract, occur mainly after exposure (route of invasion: inhalation, ingestion, percutaneous absorption).

Environmental hazards: harmful to the environment.

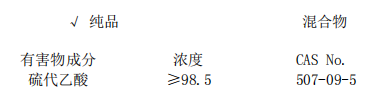

Part III Ingredient/composition information

Part IV First Aid Measures

Skin contact: immediately take off the contaminated clothes, rinse with plenty of flowing water for 20~30 minutes. If you feel uncomfortable, see a doctor.

Eye contact: immediately lift the eyelid, with a large amount of flowing water or saline rinse thoroughly for 10~15 minutes. If you feel uncomfortable, see a doctor.

Inhalation: quickly leave the site to fresh air. Keep the airway unobstructed. If breathing is difficult, give oxygen. Respiratory, cardiac arrest, immediate cardiopulmonary resuscitation. Seek medical attention.

Ingestion: drinking water, no vomiting. If you feel uncomfortable, see a doctor.

Part V Fire protection measures

Hazardous characteristics: flammable, in case of open flame, high heat or contact with oxidant, there is a risk of combustion and explosion. It is decomposed by high heat to produce toxic sulfide flue gas. It is corrosive. Thioacetic acid

Hazardous combustion products: carbon monoxide, hydrogen sulfide, sulfur oxide.

Fire extinguishing method: use mist water, foam, carbon dioxide and sand to extinguish the fire.

Precautions and measures for fire fighting: firefighters must wear full-body acid and alkali resistant fire fighting clothing and air breathing apparatus to put out the fire. Spray water to cool the container and move the container from the fire to an open area if possible. Containers in a fire scene that have discolored or produced sound from the safety pressure relief device must be evacuated immediately.

Part VI Emergency Treatment of Leakage

Emergency action: Remove all ignition sources. The warning zone shall be defined according to the influence area of liquid flow and vapor diffusion, and irrelevant personnel shall be evacuated to the safety zone from crosswind and upwind direction. It is recommended that emergency personnel wear positive pressure self-contained breathing apparatus and anti-virus and anti-static clothing. All equipment used in the work shall be earthed. Do not touch or cross the spill. Cut off the leak source as much as possible. Prevent leakage from entering water bodies, sewers, basements or confined spaces. Small amount of leakage: with sand or other non-combustible material absorption. Use clean, non-sparking tools to collect the absorbent material.

Large leakage: build embankments or dig pits to contain. Cover with anti-soluble foam to reduce evaporation. Water spray can reduce evaporation, but does not reduce the flammability of leakage in confined spaces. Transfer to tank car or special collector with explosion-proof pump.

PART VII OPERATING DISPOSAL AND STORAGE

Operation precautions: airtight operation, strengthen ventilation. Operators must be specially trained and strictly abide by the operating procedures. It is recommended that the operator wear a filtering gas mask (half mask), chemical safety protective glasses, polyethylene protective clothing and latex gloves. Keep away from fire and heat sources. Smoking is strictly prohibited in the workplace. Use explosion-proof ventilation systems and equipment. Prevent vapor leakage into the workplace air. Avoid contact with oxidants and alkalis. When filling, the flow rate should be controlled, and there is a grounding device to prevent static accumulation. Handle lightly to prevent damage to packaging and containers. Equipped with corresponding types and quantities of fire-fighting equipment and leakage emergency treatment equipment. Empty containers may leave harmful substances.

Precautions for storage: Store in a cool and ventilated warehouse. Keep away from fire and heat source. Store temperature should not exceed 37 ℃, keep the container sealed. Should be stored separately with oxidants, alkalis, edible chemicals, do not mix storage. Explosion-proof lighting and ventilation facilities shall be adopted. It is forbidden to use mechanical equipment and tools that are easy to produce sparks. The storage area should be equipped with leakage emergency treatment equipment and suitable containment materials.

Part 8 Exposure Control/Personal Protection

Exposure limits:

MAC(mg/m 3): No standard

PC-TWA(mg/m 3): No standard

PC-STEL(mg/m 3): No standard

TLV-C(mg/m 3): No standard

TLV-TWA(mg/m3):

TLV-STEL(mg/m 3):

Monitoring method: no data.

Engineering control: the production process is closed and ventilation is strengthened. Safety shower and eyewash equipment provided.

Respiratory protection: A filtering respirator (half mask) should be worn when exposed to vapors. Wear an air respirator if necessary. Thioacetic acid

Eye protection: wear chemical safety goggles.

Body protection: wear airtight protective clothing.

Hand protection: wear rubber gloves.

Other protection: smoking is strictly prohibited at the work site. After work, shower and change clothes. Pay attention to personal hygiene.

Part 9 Physical and Chemical Properties

Appearance and properties: colorless transparent liquid, pungent odor.

pH: no data

Melting point (℃): -17

Boiling point (℃): 93

Relative density (water = 1): 1.07

Relative vapor density (air = 1): no data

Critical pressure (MPa): no data available

Octanol/water partition coefficient: No data available

Flash point (℃): 2

Ignition temperature (℃): no data

Lower explosive limit [%(V/V)]: no data

Upper explosion limit [%(V/V)]: No data available

Solubility: Soluble in water, ethanol, ether, etc.

Main uses: used as chemical reagents, organic synthesis reagents, tear gas, etc.

SECTION 10 STABILITY AND REACTIVITY

Stability: Stable

Forbidden: strong oxidant, strong alkali.

Conditions to avoid contact:

Aggregation Hazards: No Aggregation

Decomposition products: hydrogen sulfide, sulfur oxide.

Part 11 Toxicological Information

Acute toxicity:

LD50:

Rat oral LD50(mg/kg): 200

Mouse peritoneal cavity LD50(mg/kg): 75

LC50:

Irritation:

Part 12 Ecological Data

Ecotoxicity:

Biodegradability:

Non-biodegradable:

Other harmful effects: no information.

Part XIII Disposal

Waste nature: hazardous waste

Disposal method: incineration method is recommended. The sulfur oxides discharged from the incinerator are removed by a scrubber.

Precautions for abandonment: refer to relevant national and local regulations before disposal.

Part XIV Transportation Information

Dangerous Goods Number: 32113

UN number: 2436

Packaging category: Class II packaging

Packing mark: flammable liquid; corrosive products

Packing method: ordinary wooden cases outside ampoules; ordinary wooden cases outside threaded glass bottles, iron cap pressure glass bottles, plastic barrels, plastic bottles or metal barrels (cans) or fixed with wrapping film; ordinary wooden cases outside threaded glass bottles, plastic bottles, composite plastic bottles or aluminum bottles or fixed with wrapping film. Precautions for transportation: railway transportation shall be carried out in strict accordance with the dangerous goods loading table in the "Dangerous Goods Transport Rules" of the Ministry of Railways. During transportation, the transportation vehicles shall be equipped with corresponding types and quantities of fire-fighting equipment and leakage emergency treatment equipment. It is best to transport early and late in summer. The tank (tank) truck used in transportation shall be provided with grounding chain, and the hole partition plate can be set in the tank to reduce static electricity generated by vibration. It is strictly prohibited to mix with oxidants, alkalis, edible chemicals, etc. During transportation, it shall be protected from sun exposure, rain and high temperature. Stopover should be away from fire, heat, high temperature zone. The exhaust pipe of the vehicle carrying the goods must be equipped with fire retardant device, and it is forbidden to use mechanical equipment and tools that are easy to produce sparks for loading and unloading. Road transportation shall be carried out according to the prescribed route, and do not stop in residential areas and densely populated areas. It is forbidden to slip away during railway transportation. It is strictly prohibited to use wooden ships and cement ships for bulk transportation.

PART XV REGULATORY INFORMATION

Regulatory information: The following laws, regulations and standards provide corresponding provisions on the safe use, storage, transportation, loading and unloading, classification and marking of chemicals:

Law of the the People's Republic of China on Work Safety (as third amended on June 10, 2021);

Law of the the People's Republic of China on the Prevention and Control of Occupational Diseases (the People's Republic of China Presidential Order No. 24, revised on December 29, 2018);

the People's Republic of China Environmental Protection Law (revised on April 24, 2014);

Regulations on the Safety Management of Hazardous Chemicals (second amendment on December 7, 2013);

Regulations on Safety Production License (2014 Amendment)

Classification and number of dangerous goods (GB6944-2012)

List of hazardous chemicals.

PART XVI OTHER INFORMATION

Latest revision date: 8 September 2021

Revision: This SDS is prepared in accordance with the Content and Item Sequence of Technical Instructions for Chemical Safety (GB/T16483- 2008).

Revision Department: Safety and Environmental Protection Department

Data Review Unit: general manager office

Description of abbreviations:

MAC: Refers to the concentration of toxic chemicals that should not be exceeded at any time within one working day at the workplace.

PC-TWA: refers to the average allowable exposure concentration of 8h working day and 40h working week specified by time.

c-ste: refers to the concentration that allows short time (15min) contact before complying with the PC-TWA.

TLV-C: instantaneous limit shall not be exceeded. It is specifically for certain substances such as irritant gases or substances with acute effects.

TL-TWA: refers to the time-weighted average concentration of 8 hours of work per day or 40 hours of work per week, at which repeated exposure to lifetime working hours does not produce adverse effects on almost all workers.

Lv-SL: It is the maximum concentration that allows workers to continuously contact for 15min under the condition of ensuring compliance with the TLV-TWA. This concentration should not exceed 4 times in each working day, and the two contacts should be separated by at least 60min. It is a supplement to the TLV-TWA.

AC refers to the International Cancer Institute

RTECS: Refers to the National Institute for Occupational Safety and Health's Chemical Toxicity Database

HSDB refers to the Hazardous Substances Database of the National Library of Medicine.

ACGIH refers to the American Conference of Governmental Industrial Hygienists

Disclaimer: Wuxue Rongtai Pharmaceutical Technology Co., Ltd. provides all relevant information comprehensively and truly in this MSDS, but we cannot guarantee its absolute universality and accuracy. This MSDS only provides safety prevention information for those who have received appropriate professional training and use the product. The individual user who obtains the MSDS must make an independent judgment as to the suitability of the MSDS under the particular conditions of use. In special use occasions, due to the use of this MSDS caused by the injury, Wuxue Rongtai Pharmaceutical Technology Co., Ltd. will not be responsible for any.

Previous Page

Previous Page

-24-hour service hotline-

+86 13699597771

Address: Wuxue City, Hubei Province, Tianzhen Office Makou Industrial Park